Services

Commercial

When it comes to hitting the road, having the right bus tyres and truck tyres in the right axle position is critical to reducing downtime, increasing ...

When you're exploring off-road trails, hauling heavy loads, or towing a caravan or trailer, you want a tyre that goes beyond the everyday. Exploring t...

Quality tyres provide you with an enhanced drive, thanks to their advanced tread patterns, high-quality construction, and special rubber compounds –...

Picking the best SUV tyres is a lot like selecting the right pair of shoes for various occasions – it depends on your specific needs and preferences...

When you work on the land you need to maximise your profits. Keeping your farm tyres well maintained with correct pressures and knowing the signs of i...

Did you know the secret to a smooth and safe driving experience is tyre traction?

If you drive, take a moment to consider how important your wheels are. They carry the weight of your ride, propel it forward, and help it stop.

We all know premature and irregular tyre wear can be a real pain. It not only costs you hard-earned dollars, but it also puts your safety at risk. Her...

Some repairs mustn't be ignored, as they can pose a real danger on the road. Here’s a look at 7 repairs that you should never put off.

Whether you’re trying to traverse some seriously rocky ground, get through the desert, or find the perfectly untouched beach, we’ve got tyres to s...

Tyres are a type of product that can be hard to understand when you first begin to research them. It turns out that they’re a lot more complicated t...

There’s nothing quite like the thrill of barrelling down the straight on a track, and preparing for the turn-in at the corner. The mind is focused a...

Getting the right performance out of a set of tyres can mean different things to different drivers, and on different vehicles. No matter what you’re...

When it comes to cheap tyres, one of the most common ways to reduce the price is to simply sell overrun stock produced for conditions that are differe...

One of the most common characteristics discussed and debated at length with regard to tyres is how long they should last. There are thousands of pages...

The SUV category of vehicle has unquestionably taken off in Australia and, along with utes and 4WDs, are some of the most popular vehicles in the coun...

From the misleadingly named Five Beach Track (it has seven beaches) in far north Queensland, to the famous Cable Beach in WA, whether it’s 75 Mile B...

Looking to deepen your understanding of tyres? Tyreright's blog post can help! From tyre anatomy to the difference between summer and winter tyres, th...

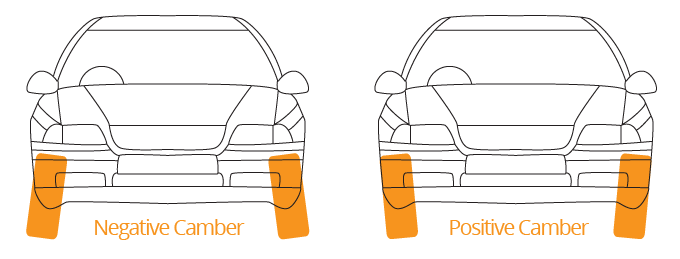

Understanding what makes your car go out of alignment can help you to avoid the hazards and kinds of driving that cost you money.

The whole point of maintaining a good wheel alignment is to minimise the resistance your tyres create by having them roll smoothly and in line with ea...

This will help us provide a personalised tyre experience.

Use my location

Select your dealership